Reducing Resource Waste in Manufacturing Processes

Manufacturing, a cornerstone of the global economy, also carries a significant environmental footprint. Inefficient processes lead to wasted materials, energy consumption, and increased operational costs. Addressing these inefficiencies through strategic interventions is crucial for both profitability and environmental responsibility.

Key Takeaways:

- Implementing resource efficiency strategies in manufacturing significantly reduces waste and operational costs.

- Data analysis and process optimization are essential for identifying and eliminating sources of waste.

- Investing in technology and employee training contributes to a more sustainable and efficient manufacturing environment.

- Circular economy principles, like material reuse and remanufacturing, offer long-term solutions for minimizing environmental impact.

Understanding the Scope of Resource Waste in Manufacturing

Resource waste in manufacturing encompasses a wide range of inefficiencies. This includes excess material consumption, energy wastage, water usage, and the generation of byproducts destined for landfills. These issues can stem from various sources, such as outdated equipment, poorly optimized processes, inadequate inventory management, and lack of employee training.

The impact of resource waste extends beyond immediate financial losses. It contributes to environmental degradation, depletes natural resources, and can damage a company’s reputation. Moreover, increasing regulations and consumer demand for sustainable products are pushing manufacturers to adopt greener practices. For example, companies that generate a large amount of data, perhaps terabytes (tb) or even petabytes (pb), might find that the processing and storage of this information consumes significant energy. Optimizing data management practices and utilizing energy-efficient servers can significantly reduce this consumption, saving potentially several gb of energy annually.

Data Analysis for Resource Efficiency

Effective waste reduction begins with a thorough analysis of manufacturing processes. Data collection and analysis provide valuable insights into where inefficiencies lie. This involves tracking key performance indicators (KPIs) related to material usage, energy consumption, and waste generation. By analyzing this data, manufacturers can identify areas where improvements can be made.

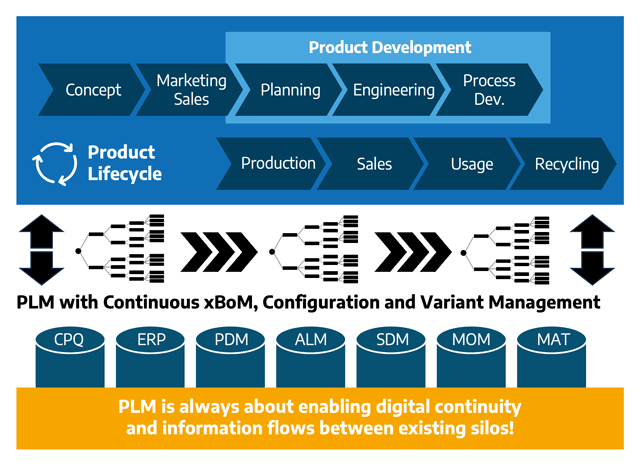

For instance, a detailed analysis of production lines might reveal that a specific machine consistently produces defective parts, leading to material waste. Or perhaps energy consumption spikes during certain hours of operation, indicating opportunities for optimization. Advanced analytics tools can help to visualize this data, making it easier to identify patterns and trends. Furthermore, using software solutions, such as Enterprise Resource Planning (ERP) systems, can offer a centralized platform to track and manage resource usage across the entire manufacturing operation.

Implementing Strategies for Resource Efficiency

Once areas of waste have been identified, manufacturers can implement targeted strategies to improve resource efficiency. These strategies may include:

- Process Optimization: Streamlining production processes to reduce material waste and energy consumption. This could involve redesigning workflows, optimizing machine settings, or implementing automation technologies.

- Material Substitution: Replacing hazardous or unsustainable materials with more environmentally friendly alternatives. For example, using recycled plastics instead of virgin polymers.

- Equipment Upgrades: Investing in energy-efficient equipment and machinery. Newer models often consume less energy and generate less waste compared to older models.

- Employee Training: Providing employees with the knowledge and skills needed to operate equipment efficiently and minimize waste. This can include training on proper machine operation, material handling, and waste segregation.

- Inventory Management: Implementing efficient inventory management systems to reduce the risk of material obsolescence and waste. Just-in-time inventory management can minimize the amount of raw materials stored on site, reducing the likelihood of spoilage or damage.

- Waste Recycling and Reuse: Establishing comprehensive waste recycling and reuse programs. This involves sorting waste materials and sending them to recycling facilities or finding ways to reuse materials within the manufacturing process.

Embracing the Circular Economy for Resource Efficiency

The circular economy offers a more sustainable approach to manufacturing by focusing on reducing waste and extending the lifespan of materials and products. This involves strategies such as:

- Product Design for Disassembly: Designing products that can be easily disassembled at the end of their life, allowing for the recovery of valuable materials.

- Remanufacturing: Restoring used products to like-new condition through disassembly, cleaning, repair, and replacement of worn parts.

- Closed-Loop Systems: Creating closed-loop systems where waste materials from one process are used as inputs for another process.

- Extended Producer Responsibility (EPR): Holding manufacturers responsible for the end-of-life management of their products.