Here’s an article designed to meet your requirements:

Building a manufacturing system that can keep pace with rapid growth is a challenge many businesses face. A system designed for a smaller scale will quickly become a bottleneck, leading to delays, increased costs, and dissatisfied customers. This article provides actionable strategies to build a manufacturing operation that can adapt and expand to meet increasing demand.

Key Takeaways:

- Prioritize flexible layouts and modular equipment to easily adapt to changing production needs.

- Implement data-driven decision-making to optimize processes and identify areas for improvement.

- Invest in scalable technology and automation solutions to increase efficiency and reduce bottlenecks.

- Focus on building a resilient and adaptable supply chain to ensure consistent material flow.

Designing for Scalable Production: A Foundation for Growth

The first step in building a scalable manufacturing system is to design with future growth in mind. This means avoiding rigid, fixed layouts and embracing flexible, modular designs. Instead of building a line optimized for a single product, consider a cellular manufacturing approach. This allows you to quickly reconfigure your production lines to accommodate new products or increased demand for existing ones.

Think about equipment in a similar way. Invest in machinery that can be easily upgraded or repurposed. Consider equipment with programmable logic controllers (PLCs) that can be modified to perform different tasks. It’s also vital to carefully consider the footprint of your equipment. Even if you don’t need all the capacity now, ensure you have the physical space to add more machines as demand increases.

Furthermore, anticipate your resource needs. Factor in storage space for raw materials, work-in-progress inventory, and finished goods. Plan for potential expansion of your workforce, including training facilities and employee amenities. A forward-thinking approach to facility design will save you significant time and money in the long run. Remember to consider that a database with 8 gb will need to be upgraded as your business grows.

Implementing Technology for Scalable Production

Technology plays a crucial role in enabling scalable production. Automation can significantly increase throughput, reduce labor costs, and improve product quality. However, it’s important to implement automation strategically. Start by identifying the most repetitive and labor-intensive tasks, and then explore automation solutions that can address those specific needs.

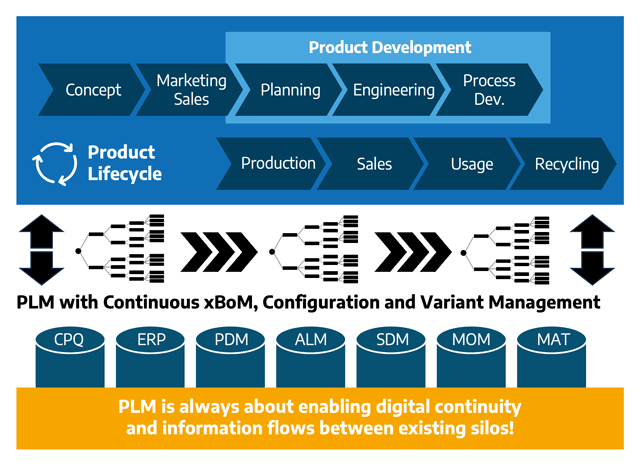

Consider investing in robotics, automated guided vehicles (AGVs), and automated storage and retrieval systems (AS/RS). These technologies can streamline material handling, improve production efficiency, and reduce the risk of human error. Implement a Manufacturing Execution System (MES) to track production in real-time, monitor equipment performance, and collect valuable data for process optimization.

Also, don’t overlook the importance of data analytics. Implement systems that collect data from every stage of the production process. Analyze this data to identify bottlenecks, optimize resource allocation, and improve overall efficiency. Data-driven decision-making is essential for continuously improving your manufacturing operations and ensuring that you can meet increasing demand.

Optimizing Processes for Scalable Production

Even with the best equipment and technology, your manufacturing system will not be scalable if your processes are inefficient. Implement lean manufacturing principles to eliminate waste, reduce cycle times, and improve overall productivity. Focus on streamlining workflows, reducing inventory levels, and improving communication between different departments.

Value stream mapping is a powerful tool for identifying and eliminating waste in your production processes. By visually mapping the entire flow of materials and information, you can identify bottlenecks and areas for improvement. Implement standardized work procedures to ensure consistency and reduce variability.

Embrace continuous improvement. Regularly review your processes, identify areas for improvement, and implement changes to optimize performance. Encourage employees to contribute ideas for improvement and empower them to implement those ideas. A culture of continuous improvement is essential for building a truly scalable manufacturing system.

Building a Resilient Supply Chain for Scalable Production

A scalable production system is only as strong as its supply chain. Building a resilient and adaptable supply chain is essential for ensuring a consistent flow of materials and components. Diversify your supplier base to reduce your reliance on any single supplier. Establish strong relationships with your key suppliers and work collaboratively to improve lead times and reduce costs.

Implement a robust inventory management system to balance the need for sufficient inventory with the cost of holding excess inventory. Use demand forecasting techniques to predict future demand and adjust your inventory levels accordingly. Consider implementing a vendor-managed inventory (VMI) program to allow your suppliers to manage your inventory levels.

Invest in technology to improve supply chain visibility. Implement a system that allows you to track materials and components from the supplier to your manufacturing facility. This will enable you to proactively identify and address potential disruptions in your supply chain. A well-managed and resilient supply chain is critical for ensuring that you can meet increasing demand without delays or disruptions.